- Home

- Printing

Partner of choice to the printing industry

Case Study: Ferag Roll Flat - Drive & Controls upgrade

Keeping your equipment running is what we do best

Our engineers / technicians provide repairs, upgrades & support for all types of equipment & applications across printing, packaging and other industries.

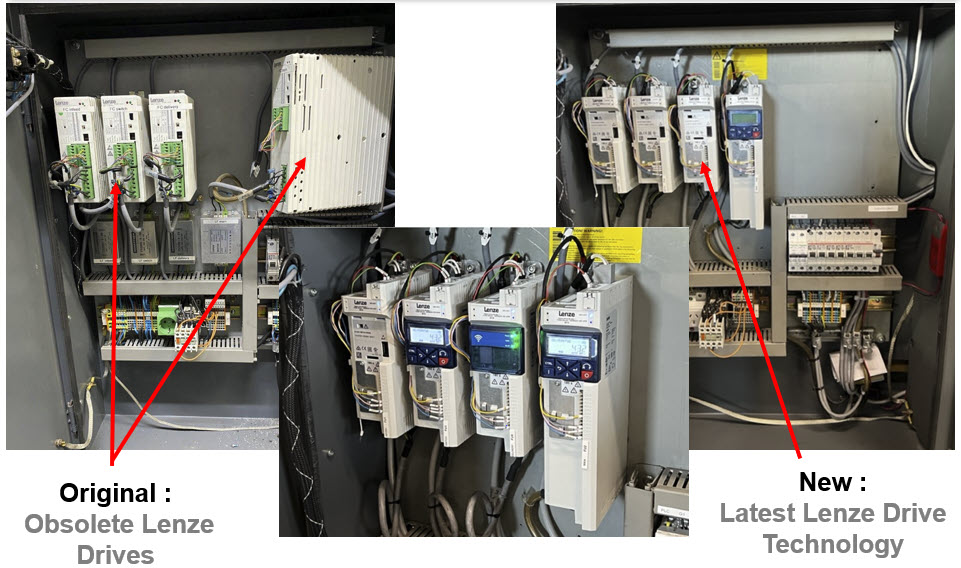

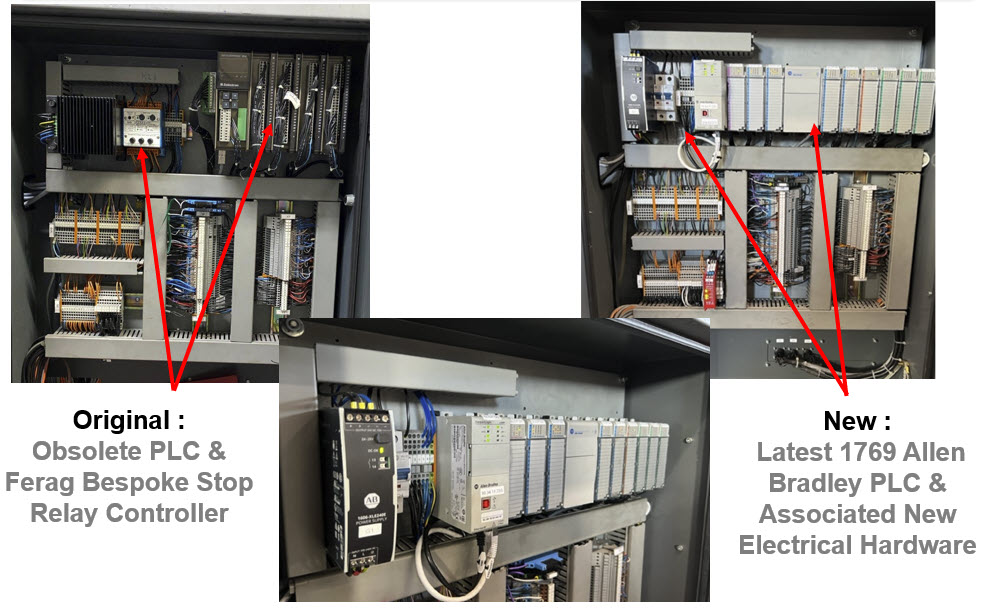

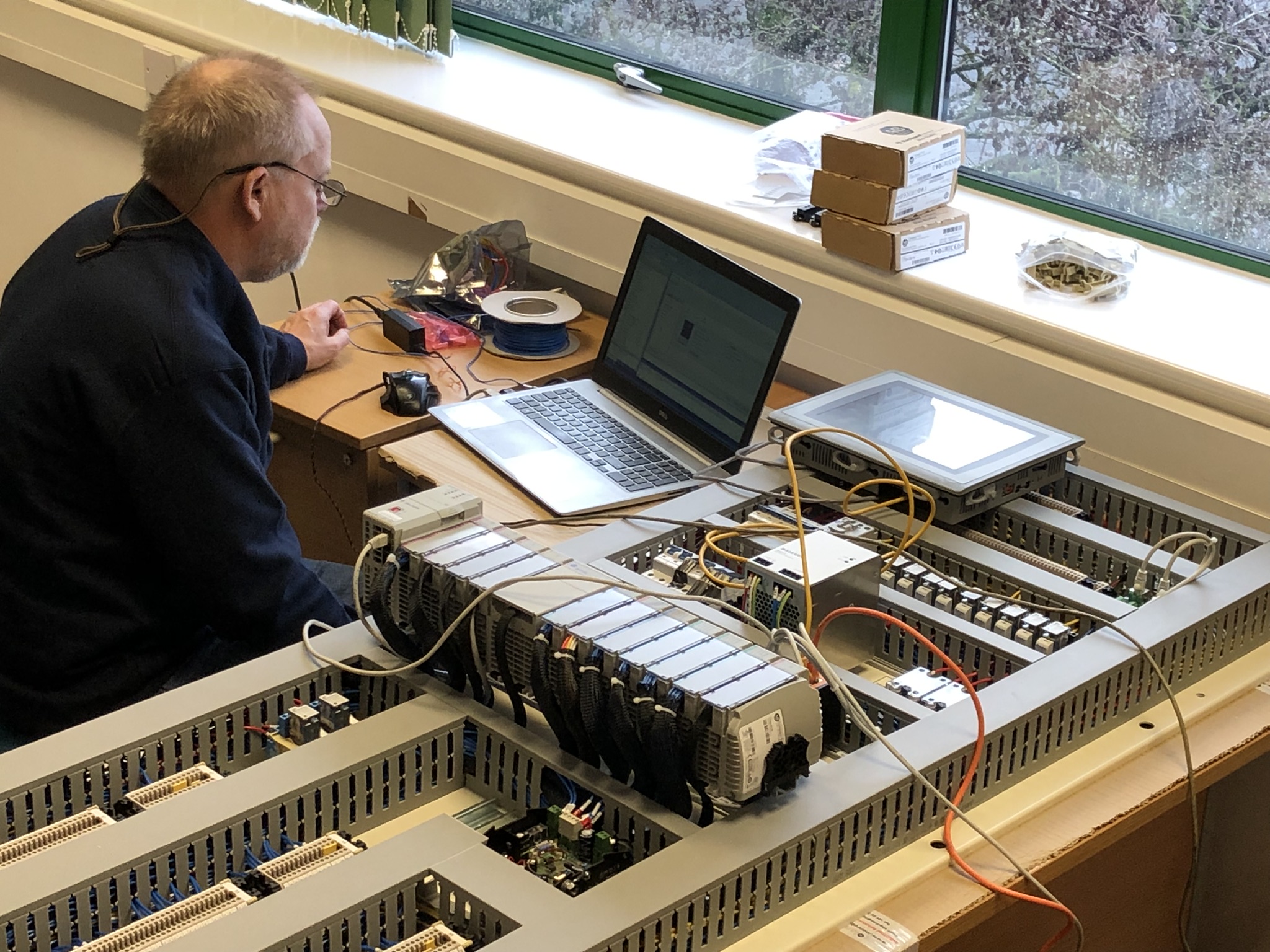

Recently our team have upgraded a number of Ferag Roll Flat machines for a newspaper customer in New Zealand

– Existing control equipment was obsolete

– Customer was finding it increasingly difficult to support

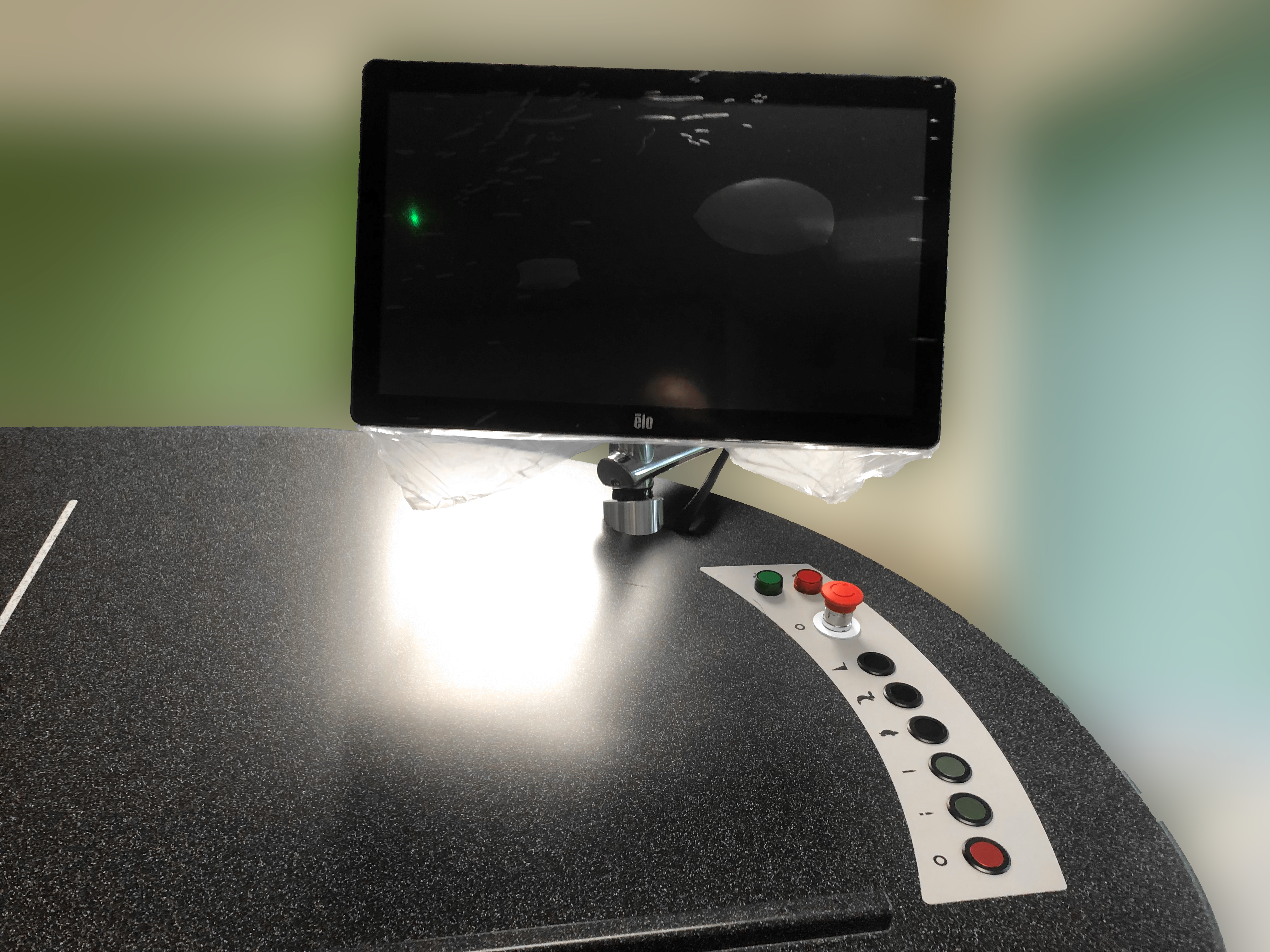

What we did:

- Site Survey - Design Engineer on site to detail machine Functionallity & Operation

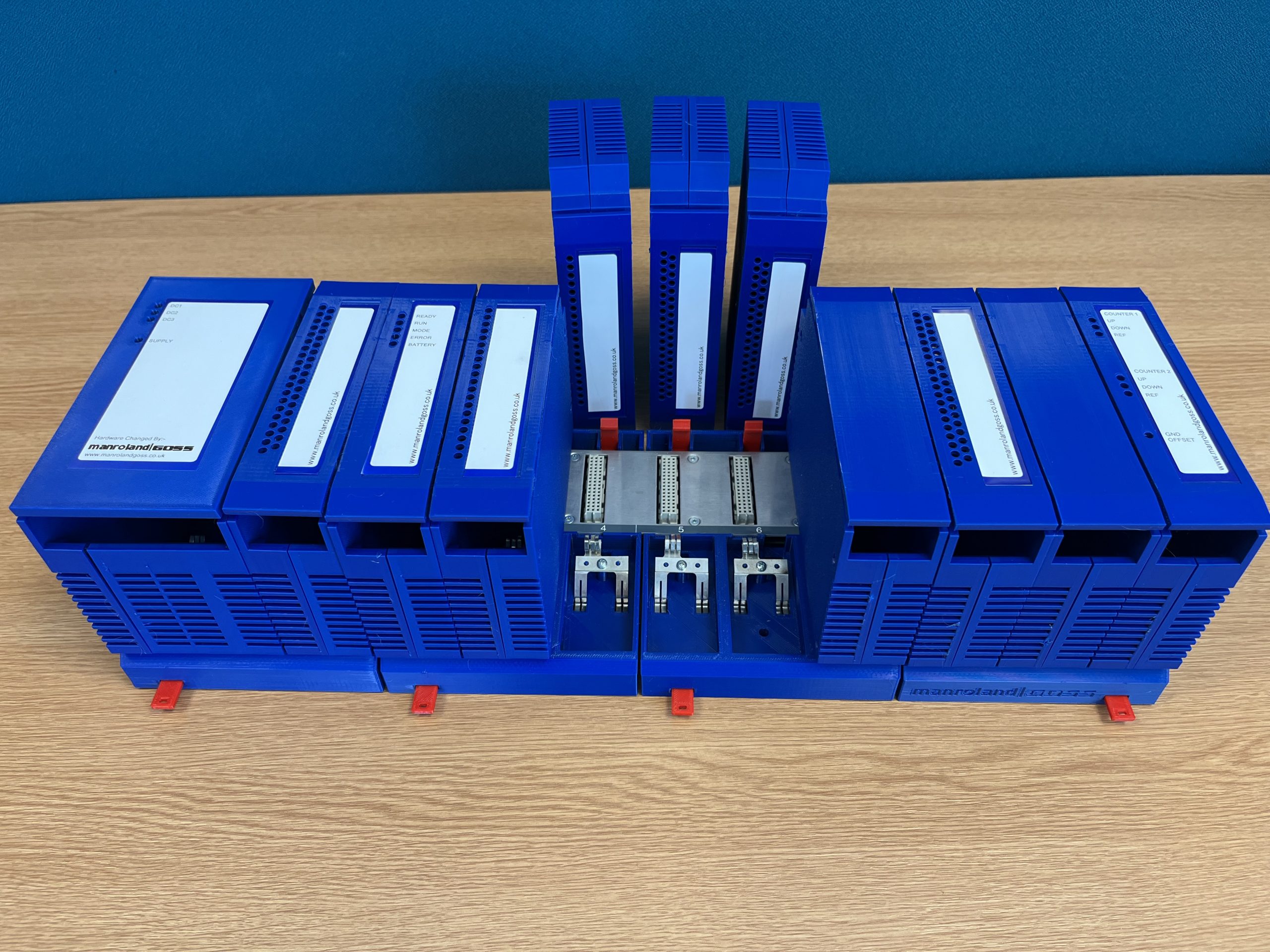

- Supply of necessary components for PLC upgrade from Selecontrol to Allen Bradley 1769

- Supply of necessary components for Drive upgrade from Lenze 8200 to latest Lenze drive

- Upgraded with latest Allen Bradley 10-inch HMI PanelView 5310

- Software Engineering - intuitive operator controls, improved alarms & messaging

- System test prior to shipment and site implementation

- Updated electrical schematics

- Installation and commissioning

- Project Management

The newly upgraded equipment is connected to our 24/7 remote support service.

We provide support for a wide range of industrial equipment and applications. From complete machine overall through to simply changing bearings or replacing components – our engineers and technicians have the expertise you need.

Case Study: Saudi Arabian Printing Client

We recently received a shipment of Bosch Rexworth Diax 03 Digital Single Axis Drives at our UK facility. The client wanted the drives to undergo a complete ‘reman’ – restoring them to ‘as good as new’ condition and ensuring they were ready for many more years of service.

All work on the drives was completed in just 4 weeks.

What we did:

- Cleaned all components & carried out initial assessment

- Replaced worn component parts

- Carried out preliminary test & function check

- Provided new type plates

- Provided a 2-year warranty

Reman is a preventative measure that reduces unplanned downtime. It also provides peace of mind through greater production reliability.

Latest Case Studies

Controls upgrade – Muller Martini ‘Zenith S 3 Knifer Trimmer’

Keeping your equipment running is what we do best. Recently our team developed an upgrade solution to modernize the outdated B&R 2005 controls platform on

Value in used Technology Assets!

🌱 Embracing the Circular Economy: Unleashing Hidden Value in Used Technology Assets! 🔄 In today’s fast-paced tech landscape, the value of sustainable practices cannot be

New control desks – Universal Press

New press control desks, for a European newspaper press customer, being prepared for transportation. x3 New press control desks MGWS press management system and RIPSet

3D Printing

Additive manufacturing, also known as 3D printing, is a manufacturing process that builds products from a digital design by depositing material in layers. The integration

Control panel upgrade – CT50 reelstand (Colorliner Mark I)

Replacement control panel design, build & testing in the UK. As part of a project upgrading CT50 reelstands on a Mark I Colorliner press. Equipped

Muller Martini TD 350 – Controls upgrade

Keeping your equipment running is what we do best Our engineers / technicians provide repairs, upgrades & support for all types of equipment & applications

Colorliner 80 press relocation – Norway

It’s a busy time for our team in Norway, with the decommissioning phase complete, the delicate and careful process of extracting the press elements from

Repair – Worn cylinder bores

Worn cylinder eccentrics & bores can affect print quality & press performance Historically the only option to refurbish the main cylinder bores was to chemically

Drive replacement

Parker SSD 590 DC digital drive Parameters pre-configured to suit customers machine. All ready to ‘plug and play’ on arrival to site in Nigeria, for

What we offer

Solving technical challenges – it’s what we do…

Maintenance & Technical Support

Maintenance & Technical Support

Repairs & Refurbishment

Repairs & Refurbishment

Solutions: Automation, Upgrades & More

Solutions: Automation, Upgrades & More

Who We Work WIth

We work with all major technologies, so we can source the right solution for your business.